FAQs

Frequently asked questions with answers. If you cannot find any answers to your questions here, please email us at [email protected]

Instructions

- Digislider 2 Axis Auto-Pan Instructions

- Digislider Extendable Single Axis Wireless Slider Instructions

- Digislider Extendable 2-3 Axis Wireless Slider Instructions

- Digislider Micro 2 Wireless Expandable Slider Instructions

- Digislider Auto-Pan 3 Axis Wireless Slider Instructions

- VT Controller Instructions - Stepper Motor

- 3 Axis Wireless Controller Instructions

- Wing Arm Instructions

- Basic Video Controller Instructions

- NMX Controller Instructions

- Pan/Tilt Instructions

Delivery

General

- Triggering problems?

- How can I get the latest news?

- What are the bearings made of?

- Is it easy to use?

- Does it need to be maintained?

- The Carriage is too tight and hard to move

- How much weight can the Digislider handle?

- Can the Digislider be mounted onto a tripod?

-

What's the best setup when shooting?

-

What cables fit which cameras?

Motors

- How much weight can the Digislider Motors handle?

- What if the belt on my motor is slipping?

- My Digislider Motor is making a high pitched noise?

Power

Payments

- Payment Errors

- Can I pay in any currency?

- I don't have a PayPal account

- I am having trouble making payment?

- Should I be paying VAT?

- The price in my cart is more than the total value of items

Instructions

Digislider 2 Axis Auto-Pan Instructions

Click here for Digislider 2 Axis Auto-Pan Instructions

Digislider 3 Axis Auto-Pan Slider Instructions

Click here for Digislider 3 Axis Auto-Pan Slider Instructions

Digislider Single Axis Extendable Slider Instructions

Click here for Digislider Single Axis Extendable Slider Instructions

Digislider 2-3 Axis Extendable Slider Instructions

Click here for Digislider 2-3 Axis Extendable Slider Instructions

Digislider Micro 2 Wireless Expandable Slider Instructions

Click here for Digislider Micro 2 Wireless Expandable Slider Instructions

VT Controller Instructions - Stepper Motor

First set the start and end points in "Settings".

Set Start point by moving the joystick in the desired direction and press down on the joystick to make the selection.

Set End point by moving the joystick in the desired direction and press down on the joystick to make the selection.

Delay (for time lapse) = Shutter delay time. Set it to about 0.5-1 seconds to allow any vibrations from the motor to settle before triggering.

Video Mode:

Manual Mode = Hold left or right joystick to move, let go to stop motors.

Auto Mode = Hold left or right on joystick to start moving, press middle button to stop.

Speed can be changed by holding up and down on the joystick to increase or decrease the speed. It can be altered whilst the motor is moving as well as when it is not.

Left and right will alter the direction.

Auto-loop will loop back and forth (ping pong mode)

Auto-stop will stop when it reaches the start or end point depending on which direction you move.

Time Lapse Mode:

Total Time = Total time you want the time lapse in hours, minutes, seconds.

Photos = How many photos you want

Exposure - Time available for exposure when the motor stops (you can change this by changing the Photos or Total Time)

Delay - The triggering of the shutter can be delayed to let the movement settle before taking a picture.

Auto-Loop - Loop back and forth (ping pong mode)

To get back to the main menu anytime just press the centre of the joystick until it clicks and hold for a couple of seconds.

Wing Arm Instructions

Time Lapse mode basic set-up

Video mode basic set-up

- If you are mounting the Wing Arm directly to the tripod legs, please tighten by holding the motor mount itself and not the Wing Arm.

- Pull up the centre locking mechanism and twist 90 degrees to unlock.

- Only move the Wing Arm by hand when the controller is disconnected from the motor.

Click here for the Wing Arm Guide

3 Axis Wireless Controller Instructions

Click here for the Digislider 3 Axis Wireless Controller Instructions

Pan/Tilt Instructions

Click here for Pan/Tilt Instructions

Delivery

How long does it take to deliver?

We aim to ship within 1 working day with UPS or Royal Mail. The following is the average delivery times:

• UK: 1 working day

• Europe: 1-2 working days

• USA & Canada: 1 or 3 working days

• Australia & NZ: 7 days

How much does it cost for delivery?

Please check out our "shipping rates calculator" at the bottom of your carts contents page - https://www.digislider.co.uk/cart

General

Trigger Problems?

Please make sure that your camera is set in the most basic/manual modes:

- Auto Focus Off (Manual Focus)

- Manual Exposure Mode (example set to 1/100" exposure and f/8 aperture)

- Live View Off

- Focus Priority Off

- Single Exposure Mode (Continuous or High-Speed Exposure drive modes may cause multiple exposures for those cameras that support it)

If your camera still doesn't fire, check the following:

- Camera appears to "wake up" (displays exposure time, etc.) but doesn't fire

- Your camera is either sleeping, or requires the focus line brought high before firing, set the pre-focus time to 200-1000mS ( Camera>Focus>200), adjust to see if the camera starts firing

- If your camera happens to force auto-focus mode, and needs more time to focus before triggering the exposure. Set pre-focus time to 2000-4000mS ( Camera>Focus Tap>2000), you may need to adjust this time depending on how long it happens to take for your camera to lock focus.

- Camera neither wakes up nor exposes

- Your camera may not work with a remote trigger in its normal firing mode, if it has a 'remote control mode' to try enabling and disabling this on the camera

- Double check that the cable is fully seated and properly orientated in the camera body and controller

If you've set everything properly on your camera and the controller and it still doesn't fire, you may have a defective cable, which we will happily replace under warranty. Please note, however, that less than 0.5% of tested cables have proven to be defective, and the only cables we've had to replace were obviously broken (broken housings, loose pins, etc.). Most non-firing situations have been resolved by adjusting camera and controller parameters.

How can I get the latest news?

Mailing List

Sign up to get the latest on sales, new releases and more …

Please follow us on Facebook and Twitter for updates too:

What are the bearings made of?"

The bearings are made of a maintenance free self lubricating special plastic that runs super smoothly and quietly on the extruded aluminium rails.

Is it easy to use?

The Digislider is incredibly easy to use. When manually operating the Digislider, it is a simple case of turning the hand crank clockwise or anti-clockwise and the carriage will move up and down the carriage with ease. With the motors, they slip on in seconds, just plug into the controller, power the controller, and move the controller knob to get it going in the same way.

Does it need to be maintained?

The Digislider is made with simplicity in mind. It is solid as a rock, and will handle all terrain and weather. If its been out in the rain, make sure it is dry before packing it away, and if it has been in the desert, make sure the bearings of the carriage and the plastic bearing that holds the shaft are free of sand. Other than that, there it is maintenance free.

The Carriage is too tight and hard to move

Make sure the carriage adjuster screw is not tight, as it will increase friction to the rail. Make sure also that the screws that attach the carriage to the linear glide bearings are only tightened when there is the correct fluidity in the movement of the whole carriage. Push down and move the carriage up and down the track to align the glide bearings before tightening the screws.

If this doesn't work try cleaning the parts of the carriage where the screws touch, including the screws, just in-case there is something obstructing and causing it not to sit properly.

If there are still problems please contact us at [email protected]

How much weight can the Digislider handle?

If there are one tripod or lightstand either end of the rail, the Digislider can handle up to 10kg when horizontal. If there is a single tripod in the centre, 5kg is a more reasonable weight for the Digislider to handle. With larger video camera tripods you can get more, but all depends on the strength and quality of the tripod you use.

What's the best setup when shooting?

We recommend a tripod head be attached to the carriage. Either a fluid video head can be attached to allow movement of the camera angle while carriage moves up and down the rail. Or a ball head for a permanent angle, best with time lapse. We recommend two supports either end of the rail for maximum support, or when doing incline shots. If you are travelling and want to pack lite, two lightstands can be used, but will be limited to horizontal shots as there is no adjustable head. It's also good to have a quick release plate attached to the rail so it can be easily slip it in and out of the tripod.

Can the Digislider be mounted onto a tripod?

The Digislider 100cm and 75cm rails have 5 x 3/8" tapped holes and 16 x 1/4" tapped holes for mounting tripods, lightstands and various other pieces of equipment on. The Digislider can be operated at floor level due to the non-marking rubber grips fitted to the bottom providing excellent sturdiness. So you can get great shots even without the support of tripods or light stands.

My Digislider has a shaking pulse action when moving the carriage quickly by hand?

Regarding the smoothness when moving the carriage by hand, the revolving handle piece will create a force on the outside away from the centre relative to the speed (the greater the speed the greater the force). This results in a shaking pulse action at higher speeds. This is just physics, and nothing we can do about it if the handle is left on. It's like the force exerted when an athlete throws a discus, as they spin, there is a constant force pushing away from the centre in the direction the arm is pointing, so when they let go the discus will go flying in that direction. It's the same as if the handle was released as it was spinning, it would also go flying. If you remove the whole handle from the pulley shaft then you will prevent this shaking pulse action exerted when moving the carriage with your hand at high speeds.

What cable goes with which camera?

Please find the correct cables here https://www.digislider.co.uk/collections/cables/products/camera-cables.

Motors

How much weight can the Digislider Motors handle?

10kg when horizontal, but you need two light stands or tripods either end of the rail for it to be stable. 5kg is really the limit for vertical and incline shots.

What if the belt on my motor is slipping?

We had to acquire smaller washers recently to incorporate the Kill Switch hole. This has resulted in belt slippage for some people when doing inclined shots. All is needed is the new neoprene adhesive sheet that has been made to solve this problem. It will also provide room for the Kill Switch. If you do not have this please let us know.

Otherwise, a slight readjustment of the motor connection onto the metal mount may help. See picture below.

My Digislider Motor is making a high pitched noise?

It is the controller's PWM (Pulse Width Modulation) circuit that produces the high pitch noise. The PWM (Pulse Width Modulation) circuit in our Digislider Controller is essential in maintaining torque at lower speeds, as it maintains voltage by pulsing bursts of it. The disadvantage is that it results in the high pitch noise you hear which stems from the vibrations of the pulses. The noise frequency is dependant on the circuit and motors themselves, different variations will output different frequencies, and often, the larger and more powerful the motors the louder the noise is. The Motor Controller MKII circuit board has been completely re-designed to reduce high pitch motor noise at the lowest speed setting.

There is however considerable less motor noise with the encased gear box than the older motors, but because of this the high pitch noise from the motor pulsing is more noticeable. Smaller less powerful motors will not emit as loud a high pitch frequency noise, but they are not powerful enough for incline shots and heavier loads. Alternatives would be: Modelcraft 600:1 motor (slow) - 9rpm - Modelcraft 50:1 motor (fast) - 104rpm - These have the same mount, so you can use the same metal motor mount and just unscrew the old motor, and only cost about £16. They will emit less pulse high pitch noise and less motor noise as they are less powerful, but they have far less power and won't work very well on inclined shots. You will have to wire it yourself, but can buy a 2.5mm x 5.5mm dc power cable for a couple of pounds or a few US dollars.

Power

Charging the 12 volt Lithium Battery.

The battery must be switched "ON" when charging, otherwise it will not charge. When the battery is turned "ON", is plugged into the charger and the charger is in the mains, both lights will be red. The charger light will go green when it is fully charged. Can take about 8 hours for a full charge.

Kill Switch

Kill Switch not functioning correctly.

Once it is set-up, we recommend you test the system. Move the carriage towards the switch with the controller, but before it gets there, press the switch with your finger. If it only slows down and does not stop, the kill switches are the wrong way around. Try it again but swap the kill switch connections in the adaptor.

Payment

Payment Errors

If you are getting payment errors, it is usually that there is a mismatch between the address on your card and the billing address you have typed in.

Banks often keep multiple addresses on file, and when you confirm an address with a bank representative, they might not be looking at the address that the verification system uses. Also, if there are any words in the address that are also numbers, such as "fifth" instead of "5th", this can cause an address to not match the records because the system checks specifically for numbers. If the bank representative sees "Fifth street" but the customer types "5th street" the system will say it is not correct because there is a "5" that the system is not expecting, but you wouldn't be able to tell which the bank representative means unless you ask specifically for the spelling of those words. The system only checks numbers, so spelling is only an issue for words that are also numbers like in my previous response. Other than that, spelling, capitalisation, abbreviation, spacing and punctuation have any effect.

Your bank would not be sending the money, just placing it on hold. It would be rejected by our payment gateway address verification settings, not the bank account it is being sent to.

Your bank does not use address verification in their approval process so it goes through on their end, and then our settings reject it later when address verification is done.

If you are still having problems, then try paying with PayPal as a guest, where you can input your card details, or with your PayPal account.

Can I pay in any currency?

All products will be charged in British Pounds, but may be paid in any currency. Our website conversion rate uses google's exchange rates, which may fluctuate slightly if/when you make the payment. PayPal will let you pay in any currency you need and will convert it so we receive the equivalent in British Pounds.

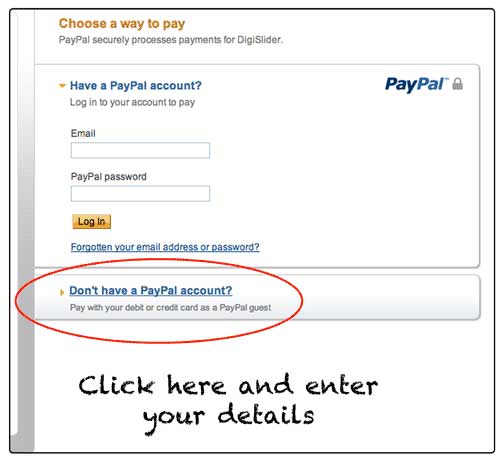

I don't have a PayPal account

You can pay with your debit or credit card as a PayPal guest.

I am having trouble making payment?

Please contact us if there were any problems with processing the order, and if you would like us to issue you a Paypal invoice to make payment instead - [email protected] or our contact page.

Should I be paying VAT?

please see the VAT page - click here

The price in my cart is more than the total value of items.

If you have previously entered your details on our website, the system often recognises it and the total in the cart will often include any tax or shipment charges. You can change or alter this once you proceed through checkout.